Βιομηχανικοί Αυτοματισμοί από την Ιδέα έως την Κατασκευή

Industry 4.0 ή απλά εκσυγχρονισμός.

Όπως και να το καταλαβαίνει ή να το εκφράζει κανείς, η εισαγωγή νέων τεχνολογιών στην παραγωγή είναι μια συνεχής, σταθερή κι απολύτως απαραίτητη διαδικασία.

Η απόκτηση του σωστού αυτοματισμού για την εταιρεία σας είναι μια περίπλοκη υπόθεση. Η Efentakis Consulting & Engineering, μελετάει συνολικά την παραγωγική διαδικασία και με την συσσωρευμένη εμπειρία των 30 χρόνων στη βιομηχανία , βοηθάει στη λήψη των βέλτιστων αποφάσεων εκσυγχρονισμού και στην υλοποίηση στοχευμένων επεμβάσεων.

Συστήματα Ελέγχου.: Είμαστε ειδικοί στα PLC, στα συστήματα ελέγχου, και στον προγραμματισμό.

Μηχανολογικός Εξοπλισμός: Με περισσότερα από 20 χρόνια μηχανολογικής εμπειρίας, η efce ειδικεύεται σε ρομποτικές εφαρμογές και βιομηχανικούς αυτοματισμούς.

Συμβουλευτικές Υπηρεσίες για Αυτοματισμούς: Είτε χρειάζεστε βοήθεια για τον καθορισμό του τρόπου βελτίωσης των διαδικασιών ή καθοδήγησης σε όλο το έργο αυτοματισμού σας, είμαστε εδώ για να σας βοηθήσουμε.

Επικοινωνια

Ρομποτικοί Αυτοματισμοί

Οι σύγχρονες απαιτήσεις για υψηλής ποιότητας προϊόντα με αυστηρές προδιαγραφές έχουν μετατρέψει τους ρομποτικούς αυτοματισμού από ένα εξεζητημένο αξεσουάρ σε έναν απόλυτα αναγκαίο εργαλείο για κάθε μεταποιητική επιχείρηση.

Οι στάνταρντ ρομποτικές εφαρμογές (όπως η παλετοποίηση) είναι ήδη προσιτές. Η efce κάνει το ίδιο και με τις ειδικές εφαρμογές που απαιτούν περίπλοκες και πολύπλοκες λύσεις.

Η efce παραδίδει εξελιγμένα ρομποτικά συστήματα. Δεν παραδίδουμε κάποια μηχανήματα. Έστω και εξελιγμένα. Παραδίδουμε μια Ολοκληρωμένη Λύση.

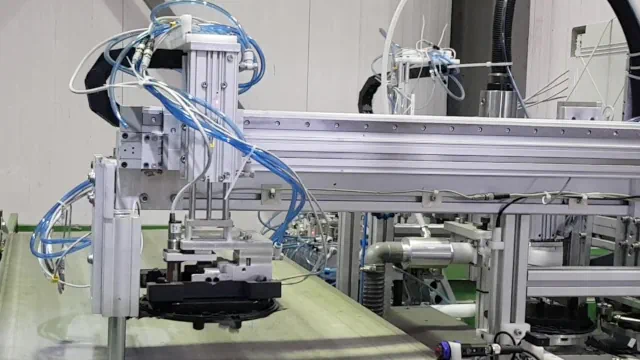

Μια τυπική εφαρμογή αποτελείται από:

- Το ρομποτικό βραχίονα. Προτιμούμε τα ρομπότ της εταιρείας FANUC. Τα γνωρίζουμε καλά κι είναι από τις καλύτερες μάρκες παγκοσμίως.

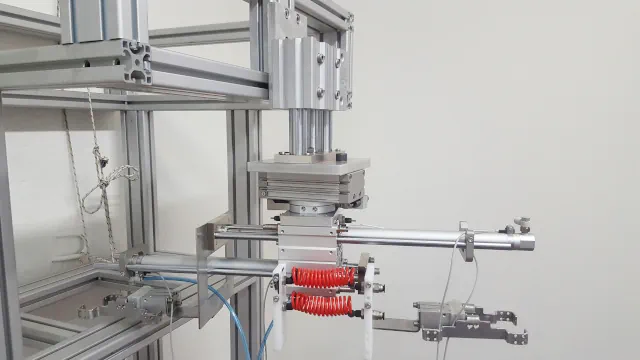

- Εργαλείο στην Άκρη του Βραχίονα (End-of-Arm-Tooling - ΕΟΑΤ). Σχεδιάζουμε και κατασκευάζουμε πολύπλοκα εργαλεία χρησιμοποιώντας εκτενώς τεχνολογίες τρισδιάστατης εκτύπωσης.

- Κεντρικός Έλεγχος Αυτοματισμού. Ένα κεντρικό PLC (προτιμούμε τα Beckhhoff Twincat PLC) θα ελέγχει και θα συντονίζει όλες τις συσκευές και θα παρέχει μια οθόνη αφής με φιλική διεπαφή με το χρήστη.

- Συσκευές ασφαλείας. Οι Κυψέλες Αυτοματισμού θα λαμβάνουν υπόψη όλους τους κανονισμούς ασφαλείας. Εμείς προτιμούμε να οδηγούμε όλα τα σήματα ασφαλείας στον ελεγκτή του ρομπότ. Εάν αυτό δεν είναι εφικτό, ενσωματώνεται ειδικός πιστοποιημένος εξοπλισμός ασφαλείας στο PLC.

- Ειδικές Συσκευές. Το Τεχνικό μας Τμήμα θα σχεδιάσει και θα κατασκευάσει όλες τις απαραίτητες ειδικές συσκευές.

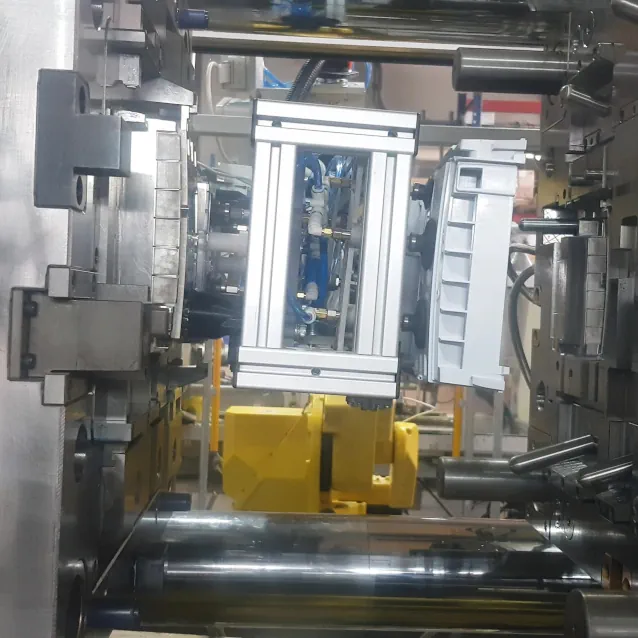

- Παραδοσιακά Μηχανήματα. Είναι σύνηθες να αυτοματοποιούνται οι παραδοσιακές διαδικασίες παραγωγής. Το efce θα προσδιορίσει την ελάχιστη δυνατή αναβάθμιση υλικού, προκειμένου να χρησιμοποιήσει παραδοσιακά μηχανήματα στη νέα ρομποτική αυτοματοποιημένη κυψέλη.

- Θα ενσωματωθεί επίσης βοηθητικός εξοπλισμός που αγοράζεται από διαφορετικούς προμηθευτές ( τροφοδότες Δόνησης κ.λπ.).

Ειδικοι Αυτοματισμοι

Για να παράξετε σωστά το προϊόν σας, η ομάδα μας είναι έμπειρη, στη χρήση κι ενσωμάτωση στον αυτοματισμό, πολλών διαφορετικών κατεργασιών, όπως pick and place, μηχανές έγχυσης πλαστικού, καθαρισμός φλας, μηχανουργικές κατεργασίες (φρεζάρισμα, τρύπημα κοκ), συγκόλληση με υπερήχους, επιθεώρηση και πολλά άλλα.

Η ανάλυση μιας παραγωγικης διαδικασίας κι η αναμόρφωσή της σε μια αυτοματοματοποιημένη γραμμή απαιτεί πολλές και σύνθετες ικανότητες, τις οποίες έχουμε αναπτύξει. για δύο όμως από αυτές είμαστε ιδιαίτερα περήφανοι:

Προγραμματισμός Διαφορετικών Συστημάτων Ελέγχου: PLCs, Embedded PCs, Programmable HMIs, Robot Controllers, Customization of CAD/CAM systems, Microcontrollers, Embedded Linux etc.

Μηχανολογία: ΅Design & Development, FEA Analysis, Design For Manufacturing, Deep Knowledge of various manufacturing processes (3D Printing, CNC Machining, Composites Manufacturing), etc.