Προτείνουμε τα κατάλληλα υλικά για την ορθή λειτουργία των παραγόμενων πλαστικών εξαρτημάτων. Έχουμε μακρόχρονη εμπειρία από όλα σχεδόν

- τα κοινά πολυμερή (όπως π.χ. η πολυστερίνη ή το πολυπροπυλένιο),

- τα «μηχανολογικά πλαστικά)» (όπως πολυκαρμπονάτ, πολυαμίδια, θερμοπλαστικοί πολυεστέρες κοκ σε αυτοσβενύμμενους τύπους και τύπους ενισχυμένους με υαλονήματα),

- έως κι εξωτικά υλικά με ακραίες ιδιότητες, όπως π.χ. το PEEK με ιδιαίτερα υψηλή θερμοκρασιακή αντοχή ή PVDF ικανό να αντέχει την υδρόλυση ακόμα και σε θερμοκρασίες κοντά στη θερμοκρασία βρασμού.

Πριν τον σχεδιασμό του καλουπιού, μελετάμε και προτείνουμε όλες τις αναγκαίες σχεδιαστικές αλλαγές που απαιτούνται για τη σωστή, οικονομική κι αξιόπιστη παραγωγή των προϊόντων σας. Αυτή η διαδικασία είναι γνωστή ως «Σχεδιασμός για Κατασκευή (Design for Manufacturability – DfM)».

Καθοδηγούμε τους πελάτες μας στην ορθή χρήση των διαφόρων τεχνικών συναρμολόγησης των πλαστικών εξαρτημάτων, όπως η συγκόλληση με υπερήχους, οι διαμορφώσεις κουμπώματος, η χρήση ειδικών κοχλιών ή περικοχλίων κι ο κατάλληλος τρόπος ενσωμάτωσής τους κοκ.

Έχουμε μεγάλη εμπειρία σε πλείστες ειδικές χρήσεις για να μπορούμε να συμβουλεύουμε τους πελάτες μας για τον ορθό σχεδιασμό και τα κατάλληλα υλικά για εφαρμογές, όπως η ασφαλής επαφή με το ηλεκτρικό ΄ρεύμα, η συμπεριφορά των πλαστικών σε ακραίες καιρικές συνθήκες, η εξασφάλιση συνθηκών στεγανότητας, οι χρήσεις που υπάρχουν προδιαγραφές ακαυστότητας κοκ

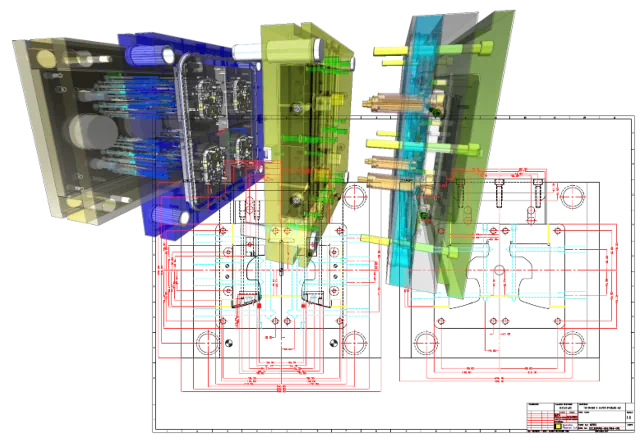

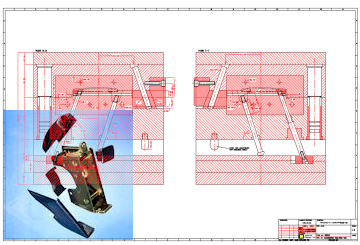

Παραδίδουμε λεπτομερή σχέδια των καλουπιών, προσαρμοσμένα στις ιδιαίτερες ανάγκες κι απαιτήσεις των κατασκευαστών, είτε αυτοί είναι δικοί μας συνεργάτες είτε είναι επιλογή των πελατών μας.

Παρέχουμε τεχνικές συμβουλές τόσο στη διαδικασία της επιλογής των μηχανουργών και των παραγωγών των πλαστικών εξαρτημάτων, αλλά και στην παρακολούθηση κι εποπτεία τους.

Μπορούμε ακόμα να προτείνουμε δικούς μας συνεργάτες για την κατασκευή των καλουπιών και την παραγωγή των τελικών προϊόντων.

Επικοινωνια Σχεδιασμός για Δυνατότητα Κατασκευής (DFM)Έχουμε σχεδιάσει καλούπια σχεδόν για τα πάντα!

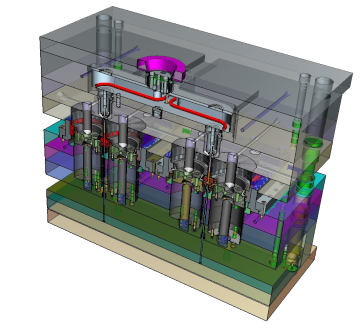

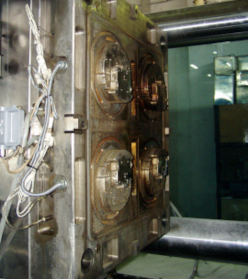

Σύνθετα καλούπια για τεχνικά εξαρτήματα, κατασκευασμένα από μηχανολογικά θερμοπλαστικά υλικά, για απαιτητικές εφαρμογές. Αυτή είναι η τεχνογνωσία μας.

Έγχυση Δύο Υλικών (2K)

Καλούπια για παραγωγή εξαρτημάτων από πολλά υλικά. Συνδιασμός Σκληρού-Μαλακού Υλικού, Παραγωγή εξαρτημάτων με δύο χρώματα.

Αυτοκινητοβιομηχανία

Τεχνικά εξαρτήματα σε χρήσεις κοντά στη μηχανή (κάτω από το καπό). Συνήθως από υλικό PA66GF30.

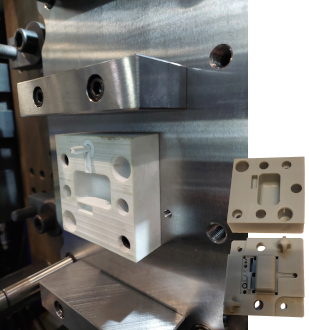

Καλούπια από τρισδιάστατη εκτύπωση

Καλούπια με ένθετα από τρισδιάστατη εκτύπωση. Για γρήγορη κι οικονομική παραγωγή εξαρτημάτων με προδιαγραφές σειριακής παραγωγής (μέχρι μερικές δεκάδες ή λίγες εκατοντάδες εξαρτήματα).

Καλούπι Παραγωγής BMC (Bulk Molding Compound)

Η BMC είναι μια μέθοδος παραγωγής με χύτευση που γεφυρώνει τη χύτευση με έγχυση με την παραγωγή σύνθετων υλικών.

Ειδικά Μηχανολογικά Υλικά

Τεχνικά Λειτουργικά Εξαρτήματα από υλικό PEEK, PEI, PPS, PPSU κλπ.

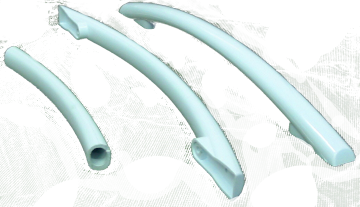

Ειδικές Εφαρμογές Εξωτερικών Χώρων

Σύνδεσμοι για Σχάρες Αυτοκινήτων.

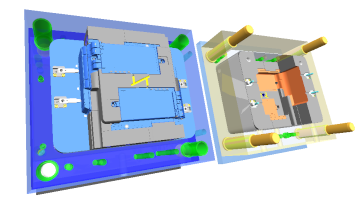

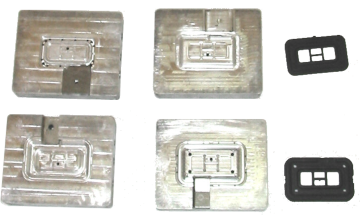

Ηλεκτρονικά/Ηλεκτρολογικά

Θήκες για Ηλεκτρονικά, Μετρητές Ενέργειες, και Καταναλωτικά ή Βιομηχανικά Προϊόντα. Συνήθως από βραδύκαυστα ή αυτοσβενύμμενα υλικά και υψηλές αισθητικές απαιτήσεις.

Καλούπια Μικρων Σειρών

Καλούπια από Αλουμίνιο για δοκιμαστκές παραγωγές ή για μικρές σειρές παραγωγής, (μερικές χιλιάδες εξαρτήματα).

Αεριοβοηθούμενη Έγχυση (GAI - Gas Assisted Injection Molding)

Εξαλείψτε τις στρεβλώσεις και τα ρουφήγματα. Εξοικονομήστε πολύτιμο υλικό. Χρησιμοποιείστε μικρότερες μηχανές Injection.

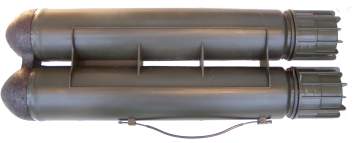

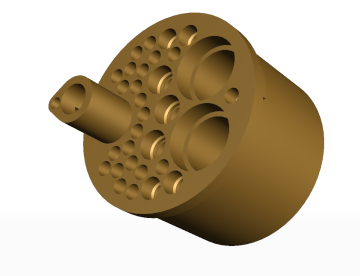

Αμυντικό Υλικό

Καλούπια για θήκες πυρομαχικών πεδίου & περιβλήματα για αμυντικά ηλεκτρονικά. Υλικά Στρατιωτικών Προδιαγραφών. Ειδικές Περιβαλλοντικές Προδιαγραφές.